Surface Mount Technology

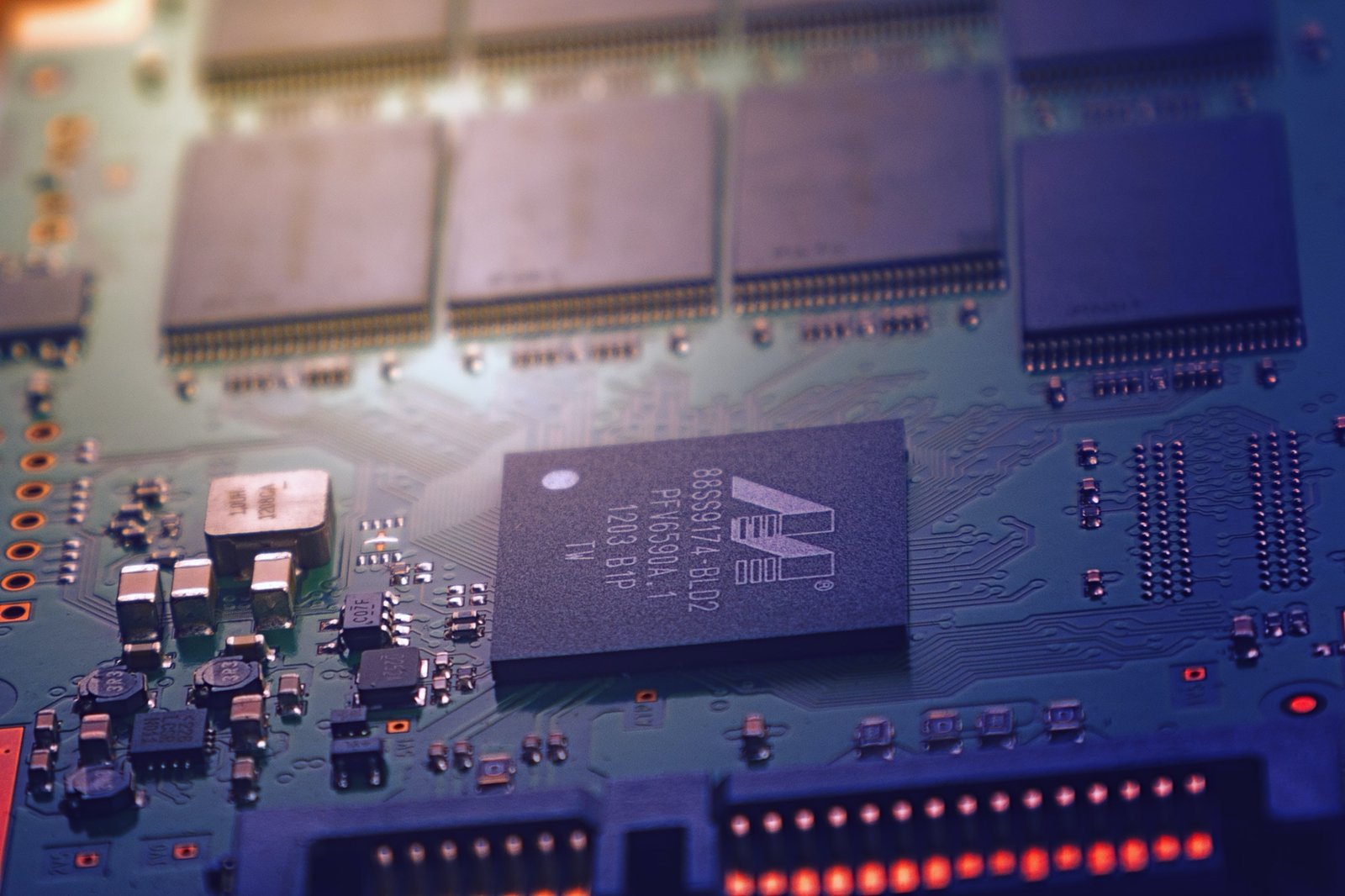

Surface Mount Technology

In our 30 year history, surface mount assembly has changed significantly. But with our commitment to ongoing capital expenditure we ensure we are always at least one step ahead of our customer’s requirements with qualified equipment and processes capable of handling the most advanced component packages. We Feel that Pavecost Manufacturing boasts one of the most sophisticated and advanced SMT manufacturing capabilities in the UK.

BGA

For over 10 years Pavecost Manufacturing have been assembling PCB’s with BGAs, and now routinely assemble products with multiple BGA and uBGAs on both single sided and double sided boards. Over the years we have paid particular attention to the stencil design. We will assess the pitch and ball size and resulting aspect ratio for the stencil. Depending on those results we will recommend standard laser cut, laser cut with an etched step, or an electroformed stencil with specific thicknesses to suit. As part of our normal manufacturing process we will X-Ray and AOI Inspect all BGAs. By having x-ray and AOI inspection we are always 100% confident that our processes are perfectly set up.

Miniaturisation

Our equipment and processes are qualified down to 0201 size components. We always strive to be at least one step ahead and have therefore invested in surface mount placement, along with all the other steps in the process including inspection and test, for the assembly of these tiny parts.

CHIP on CHIP

Chip on Chip, or Package on Package (PoP) is an emerging technology whereby one component is placed directly onto pads on the top of a previously placed component.Over the last year we have taken time to obtain samples, attend SMART group conferences, review process requirements with TDK and Suzuki etc. As a result we are in a position to assemble these types of devices as and when the need arises. However, we would recommend that prior to finalising a layout you discuss the manufacturability of these parts and your product as our success will be greatly influenced by your design.

At Pavecost Manufacturing we have 3 fully integrated surface mount lines for main production, with a combined output of 200,000 CPH.

Some of our manufacturing equipment includes:

- SPEEDPRINT SP710AVI full automatic screen printer with 3D inspection & glue option

- SPEEDPRINT SP210AVI full automatic screen printer with 3D inspection

- YAMAHA YSM10 Compact High Speed Modular Multi Function Pick & Place up to 46,000 CPH

- YAMAHA YSM20 High Efficiency Modular Multi Function Pick & Place up to 95,000 CPH

- ESSEMTEC RO400FC Multi zone reflow oven built in profile/prediction software

- HELLER 1826MK5 Convection Reflow oven for high volume

- ERSA HOTFLOW 5 Reflow Oven

- DCB AUTOMATION UltraVision Full colour with laser height check AOI inspection system

We have invested considerably in off line set up facilities including additional feeders and carts to allow the rapid change over of jobs and ultimately improving lead-times for our customers.

QUESTIONS?

Whether you’re curious about our capabilities or you have a requirement that you would like our help with, we’re here to answer any questions.